Aircraft Propellers - Although there have been many innovations in propeller design over the past century, the basics have remained the same. The Wright brothers created the first truly effective propeller blades when they rejected the prevailing idea at the time that an airplane propeller should be shaped like a propeller. Instead, they envision a propeller designed like a twisted wing that "pulls" the plane through the air, creating thrust.

The concept of propeller thrust is best explained by Newton's third law of motion. For every action there is an equivalent opposite reaction. Thus, as the propeller rotates and draws air behind it, it simultaneously pushes the aircraft forward with equal force. The more air is drawn in behind the plane, the more the plane is pushed forward.

Aircraft Propellers

The reason propeller blades are curved is so that they can cut or bite the air rather than simply pushing it. By changing the pitch or pitch of the propeller, you can change the amount of air it draws in to create thrust or thrust.

Airplane Propeller Design History

These fundamentals of propeller design have changed little over the past century. Changing the propeller pitch, materials, or adding propeller blades helps increase speed, rate of climb, reduce noise, and efficiency, but the basic physics remains the same. You know that propellers create thrust, but how does it actually happen? The answer is simple and it all comes down to how the lift is created and directed.

According to NASA, “A rotating propeller creates a pressure lower than the free flow in front of the propeller and higher than the free flow behind the propeller. Beneath the disc, the pressure eventually returns to free-flow conditions. But at the exit, the speed is greater than the free flow, because the screw is active in the air flow. We can apply Bernoulli's equation to the air in front of the propeller and to the air behind the propeller.”

Propellers are aerofoils shaped like wings. But instead of producing vertical lift, propellers create forward lift, which we call thrust. (We'll cover this below)

Like wings, propellers have camber and chord lines in addition to the leading and trailing edges. If you look closely at the propeller, you will also notice that the angle of the blade varies from root to root.

Basic Types Of Aircraft Propeller That Most Of You Don't Know

As the propeller rotates around the crankshaft, the speed of the propeller blades is higher at the top and lower at the root. In one full turn, the tip of the blade must travel a greater distance than the root of the sword, all at the same time. That is why the angle of the blade is the largest at the root, and the smallest at the tip. By "twisting" the blades, you get the same angle of attack across the entire propeller blade.

If the angle of the blade were the same everywhere, the force of traction and pressure would vary greatly from root to root. There may be an incorrect angle of attack at the root, and the blade will dull at the end. This is why the angle of the different blades plays such an important role in preventing a large angle of attack and changing blade pressure.

The simple purpose of the propeller is to convert the braking force of the engine into thrust. Like wings, propellers accelerate airflow over their curved surface. High wind speed results in low static pressure in front of the propeller, pulling the airfoil forward.

To accelerate the plane, the thrust must be greater than the drag. As engine power and propeller speed (RPM) increase, the air becomes faster across all blades, creating a strong pressure difference, pulling the aircraft forward. This speeds up the plane, but is limited by available thrust. If you fly faster than L/D max, more power is required to compensate for the increased parasitic drag. As acceleration increases, the load on the resistance also increases. Because of this, at higher wind speeds, more power is required for acceleration.

Old Plane Propeller Free Stock Photo

Propeller efficiency also plays a large role in acceleration. At about 80% efficiency, any increase in headwind speed results in a loss of efficiency for a fixed-pitch propeller. This lack of efficiency at high speeds also reduces available drag and power.

In an ideal world, a variable pitch propeller would work best, with a large pitch for low wind speeds and a small pitch for high wind speeds. Due to design, handling and weight issues, variable diameter screws are impractical. Instead, the range of most propellers is limited to provide a "happy medium" between slow and fast winds.

Propellers convert engine power into thrust by accelerating air and creating a low pressure difference in front of the propeller. Because air naturally moves from high to low pressure, when your propeller turns, it pulls forward. An Airmaster propeller will increase the efficiency and safety of your aircraft in all phases of flight. Simply select flight mode on the green controller to select the correct engine RPM.

Airmaster can offer a complete propeller system for any type of aircraft, be it short range, cruise, high altitude or sea.

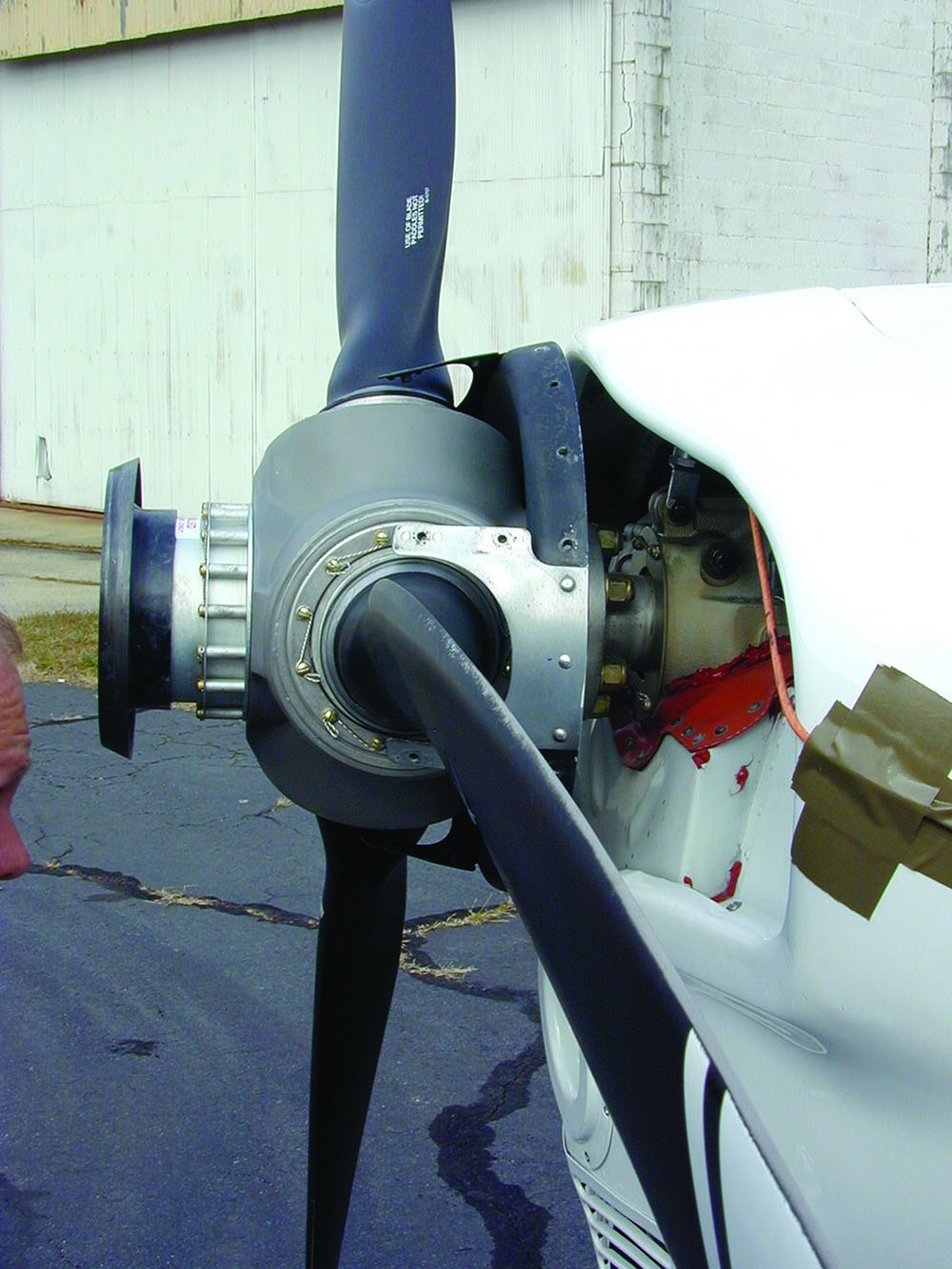

Spinner Upkeep: More Than Aesthetics

The one-piece sleeve shell is designed to withstand high loads during flight to ensure long life.

The high-strength mounting assemblies are designed to withstand the high loads typical of aircraft, while remaining easily removable for maintenance and inspection of the propeller.

High-quality servo drives from Maxon (Switzerland) provide fast and accurate step adjustment during a long service life.

Phosphor bronze slip rings are corrosion resistant, providing reliable screw feed under the toughest conditions.

Georgia College Student Killed By Plane Propeller At Airport While On Date

To simplify the operation of the screw system, modern digital devices are used. An intuitive blue selector is used to set engine speed, while colored indicators ensure proper propeller operation.

Airmaster offers a wide range of standard products. Visit the products page and use the product filter to narrow your search

Instructions for the blade assembly procedure. Instructions for installing the blade assembly into the sleeve.

Colin Kelly Tecnam P2008 Rotax 912ULS Airmaster AP332SCTFH Whirlwind R68W "One of the best options for my money."

Dji Fpv Ludicrous Upgrade Propeller Set X4 Red

Dion Buchanan Lancair 235 Lycoming O-235 Airmaster AP433 Whirlwind R63U "The propeller saw the power of the Lancair 235"

Mike Smith Progressive SeaRey Rotax 914 Airmaster AP332R Wirwlwind L70Z "Couldn't be happier with the propeller."

Novosibirsk Squadron Aeroprakt A-22 Rotax 912ULS Airmaster AP332 Warpdrive R68T "We were the first in the world to install Airmaster on an A-22."

Bjørnar Jakobsen TL-3000 Sirius Rotax 912ULS Airmaster AP430 Sensenich R68C "The performance improvement over a standard propeller is impressive."

Wings And Propellers Of All Sorts And How They Work

Don Maxwell Progressive SeaRey Rotax 914 Airmaster AP332R Wirwlwind L70Z "Altitude changes are quick and reliable and the controller is intuitive and easy to use."

Ruan Rezende Seamax Rotax 912S Airmaster AP332 Warp Drive T67L "We work with Seamax/AP332 on Amazon."

AP332CTF-WWR68W Airmaster Propeller System Rotax 9 Series AP332S Engine 68" Diameter Bushings Whirlwind Composite Blades W Profile

AP330CTF-WWR64W Airmaster Propeller System Rotax 9 Series AP330 Engine 64 Inch Diameter Bushings Whirlwind Composite Blades W Profile

Johnson Propeller Enterprise

Product Code Translation Article Product Code Translation Explanation of the codes used to describe propellers in the Airmaster system

Andrii Sokovets Chaika L-42 Rotax 912S Airmaster AP332F Warpdrive R72T "Russian builders tested different types of propellers and approved only "AIRMASTER".

If an existing product is not suitable, Airmaster can create customized solutions using a variety of components. Each component can be configured in a variety of ways for greater flexibility.

Propeller hubs come in various shapes and sizes from 2 to 4 blades and in the HP range from 80 to 200.

Can A Propeller Driven Aircraft Break The Sound Barrier?

Choosing the right blade is critical to maximizing the performance of the propeller system. Airmaster works with the best blade manufacturers from around the world to ensure the best blades are used in every situation.

The AC200 digital controller provides fast and accurate volume control in any situation. It is available in many variants designed for specific applications and is fully customizable for use on multiple engines.

High quality aluminum spinner cones are available in a variety of sizes and finishes to provide the perfect finish for every flight.

Many extensions, spacers and adapters are available to make your propeller a perfect fit for your aircraft

Single Engine Propeller Plane On Runway, Head On View Stock Image

All associated parts such as support springs, power looms, brackets and hardware are available for installation on various engines. New parts are constantly being added, please ask.

We have a large collection of our customers' experiences in the testimonials section. Take a look and try to filter out the ones that match your type of aircraft (lower the filters on the left)Date: December 19, 2018 Category: Blog Tags: aircraft propeller, aircraft propellers, aviation, Hartzell history, Hartzell Propeller, propeller, wright brothers

Aviation has come a long way since the Wright brothers first looked into the sky in 1903. Just as airplane design has evolved since the beginning of powered flight, so have airplane propellers. Here's a closer look at the evolution of the airplane propeller:

The first versions of the screw were taken from

Mt Flight Tests Propeller With 11 Blades On A Piper Cheyenne

Rc aircraft propellers, ultralight aircraft propellers, model aircraft propellers, sensenich aircraft propellers, carbon fiber propellers aircraft, vintage aircraft propellers, mccauley aircraft propellers, aircraft propellers design, used aircraft propellers, aircraft wood propellers, antique aircraft propellers, aircraft propellers for sale

0 Comments